High-Quality Metal 3D Printers using SLM Technology FS200M

Metal Printer

Category:

Metal Printer

Product accessories:

Contact Us

Product description

Compact and flexible layout

High integration, covering only 3.48 square meters

Forming cylinder size 425 × two hundred and thirty × three hundred

Maximize the production capacity per unit area of the plant

Extreme printing efficiency

Stable and mature two-way powder spreading technology

Unique dual-laser scanning strategy, greatly improving efficiency

Develop multi-layer thick printing process based on actual needs

Optional automatic grafting function, grafting accuracy<0.1mm

Stable operation for a long time

Upper powder feeding+mobile powder feeding device, supporting powder supply of multiple equipment

Equipped with ambient oxygen monitor, all exhaust gases are filtered by H13 filter element

Scientific wind farm structure design to achieve smooth and clean printing operation

Low cost and convenient operation

The multistage circulating filtration system is upgraded with powerful backwash function, and the service life of the filter element is more than 1200h

Equipped with mobile powder feeding device to realize continuous powder without stopping and support multiple equipment for powder supply

The construction platform height is reasonable, and the base plate installation and removal process is more convenient

技术参数

| Overall Dimension (L × W × H) |

2320×1500×2700 mm |

|

Forming Cylinder Size1 (L×W×H) |

425×230×300mm(Including the thickness of formed base plate) |

|

Standard Substrate Size (L×W×H) |

420×225×40mm |

|

Net Weight Of Equipment |

About 2050 kg |

|

Thickness Of Powder Layer |

0.02 - 0.1 mm adjustable |

|

Scanning Speed2 |

Up to 10 m/s |

| Laser System |

Double laser(2×500W) |

|

Galvanometer Scanning System |

High-precision scanning galvanometer |

|

Inert gas consumption (printing process) |

3 - 5 L/min (nitrogen/argon) |

|

Operating System |

64-bit Windows10 |

| Data processing and system control software |

BuildStar, MakeStar® |

| Software Function | Open source parameter adjustment, real-time modification of construction parameters, 3D visualization, diagnosis function |

| Data Format |

STL |

| Power Requirements |

380V,3~/N/PE,50/60Hz |

| Operating ambient temperature |

25±3℃ |

|

Forming Material |

Titanium alloy, aluminum alloy, die steel, stainless steel, superalloy, etc |

Accessory Equipment

Aerospace

Fuel injector

Aerospace

Aircraft radiator

Automobile industry

Racing lightweight connector

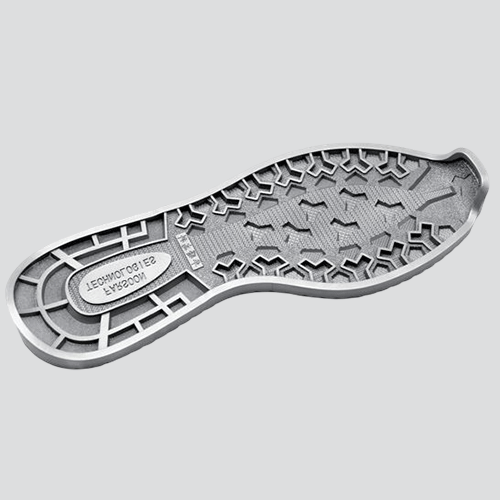

Mold industry

Shoe mold

Intelligent module

Standard configuration

Online real-time modification of construction parameters, 3D visualization, diagnosis function, support addition function, temperature field control, remote monitoring, data feedback and integrated control, etc.

Optional

Automatic grafting function

Supporting supplies

General consumables

Scraper, base material, filter element

Powder consumables

Titanium alloy, aluminum alloy, die steel, stainless steel, superalloy, etc

Related Products